4WEB Clinical Publication | Article 3 of a 4-Part Series

10 . 05 . 22

Strains in Truss Spine Interbody Fusion Implants are Modulated by Load and Design

Optimizing Structural Efficiency to Improve Implant Performance

ABSTRACT

An ovine fusion study showed that Truss Implant TechnologyTM provides design elements that can be optimized to accelerate the fusion process. These results led to the focus of this study, which evaluated the range of micro-strain found in the truss elements and overall structural efficiency, defined as relative strain distribution in the total number struts.

BACKGROUND

Spinal interbody fusion devices with an open architecture truss design provide a platform to produce implants that deliver targeted mechanical stimulation to the surgical site. Optimizing these designs can lead to development of therapeutic implants that improve clinical outcomes.

METHODS

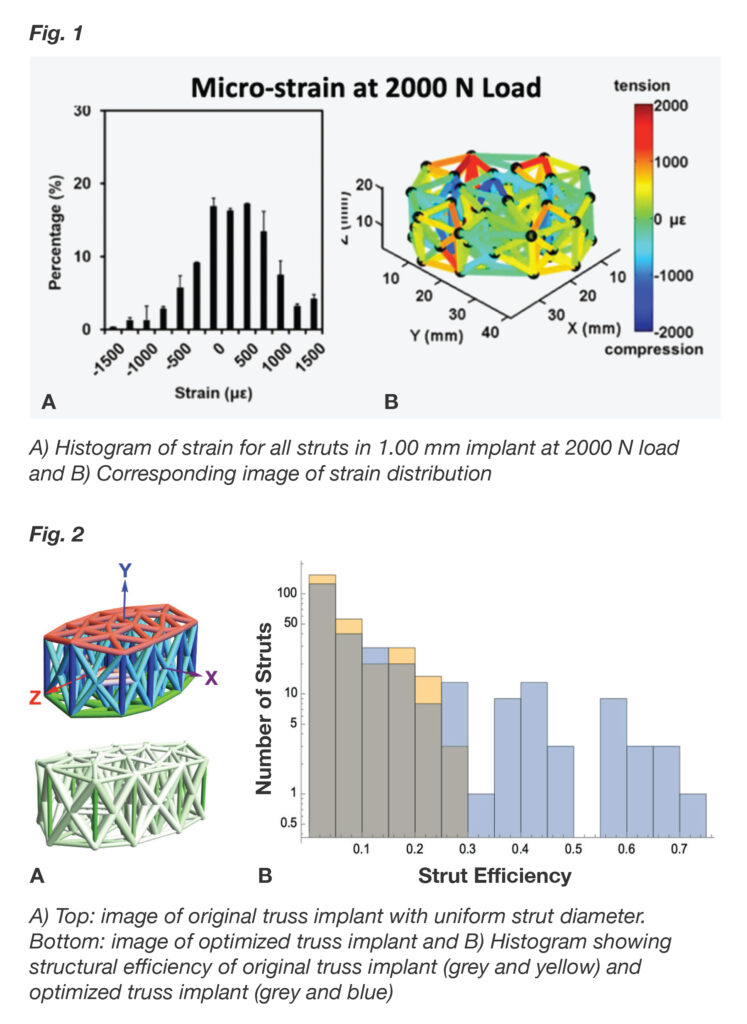

Truss implants with uniform strut diameters (1.00 mm or 0.75 mm) were mechanically loaded (1000 N and 2000 N). The implants were imaged using high-resolution micro-CT during loading. The deformation and strain of each strut was determined at different loads by tracking the displacement between fiducial markers attached to strut intersection points. The strain profile for each strut was calculated to assess structural efficiency.

RESULTS

Strain amplitudes increased 42%, from 346με at 1000 N to 492με at 2000 N, for the 1.00 mm implant. The increase in strain amplitude for the 0.75 mm implant at both loading conditions was similar; however, the 0.75 mm implant had a 39% higher average strain amplitude compared to the 1.00 mm implant. These amplitudes correspond to the mechanobiological range of bone homeostasis and formation, with 63±2% (p<.05 vs. other groups), 72±3%, and 73±1% of struts within that range for the 1.00 mm at 1000 N, 1.00 mm at 2000 N, and 0.75 mm at 1000 N, respectively. A related study was conducted to evaluate opportunities to improve structural efficiency. The optimization process resulted in a 225% increase in overall structural efficiency by increasing the relative strain distribution in the total number of struts.

CONCLUSION

This study extended beyond micro-scale mechanical characterization of truss implants and evaluated the effect that changes to the truss design elements have on the structural

mechanics of the device when subjected to moderate (1000 N) and strenuous (2000 N) load levels. The findings suggest that truss interbody fusion implants can be designed to deliver mechanobiologic strain to the surgical site under physiologic loading conditions.