4WEB Clinical Publication | Article 2 of a 4-Part Series

09 . 28 . 22

Subsidence Resistance of Additively Manufactured Cages in Foam Substrates: Effect of Contact Topology

Addressing the Clinical Needs of High-Risk Patients Utilizing Implants with an Advanced Structural Design

Collino, Rachel R. PhD; Kiapour, Ali PhD; Begley, Matthew R. PhD

ABSTRACT

A snowshoe’s primary function is to efficiently distribute load over a projected area to prevent penetration into a material that has a low relative density. This concept is well understood and has been characterized through engineering principles such as contact mechanics. To evaluate how these principles apply to bone-implant contact surfaces of spinal interbody implants, a study was conducted to characterize the influence a truss implant’s snowshoe interface has on resistance to subsidence.

BACKGROUND

Legacy implant designs incorporate an annular or ring shaped geometry with a large open space in the middle of the implant. Annular shaped implants cause high contact stress points on the perimeter of the vertebral body that can lead to subsidence related complications. Implants with advanced structural designs can now be produced with features that improve upon legacy implant design flaws, reducing subsidence related complications.

METHODS

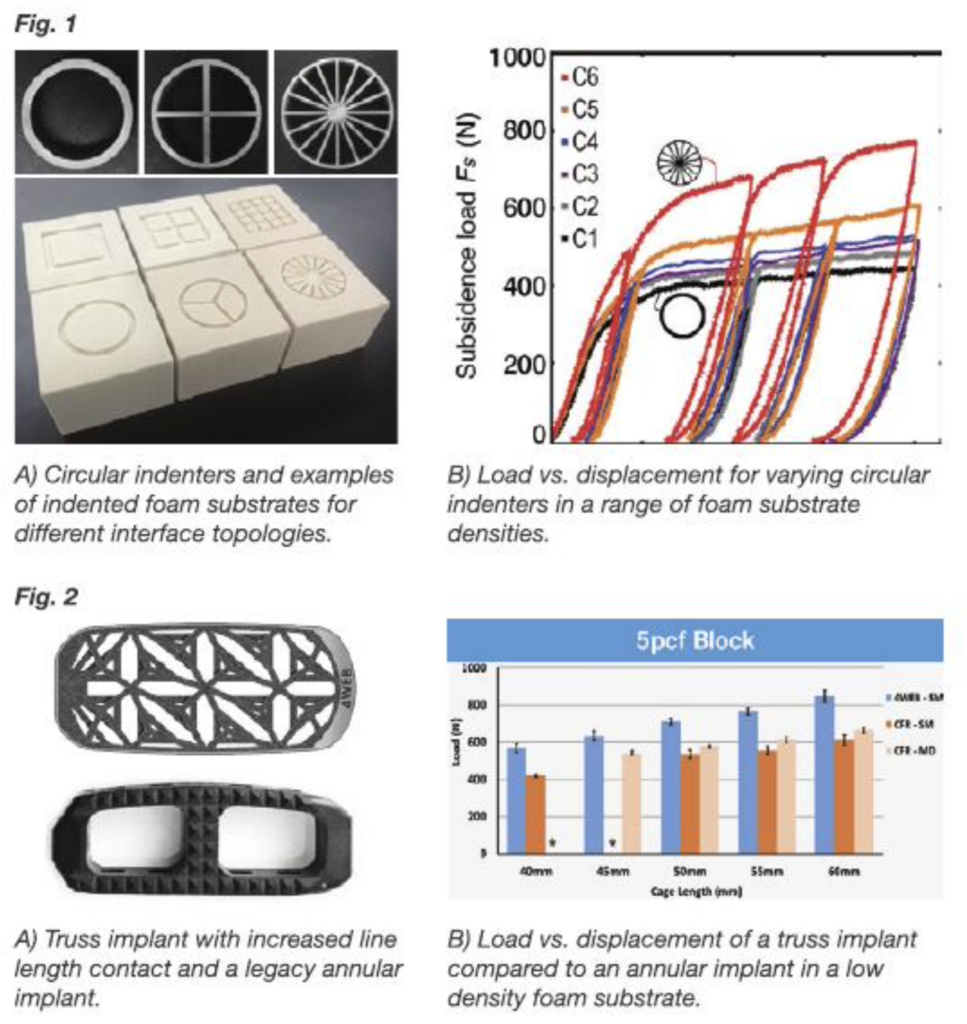

To isolate the effect of contact topology, the indentation behavior of different interface topologies was analyzed (Fig 1). The indenter topologies were tested against a range of rigid, closed-cell polyurethane foams that mimic the modulus and compressive strength of human cancellous bone.

RESULTS

It was determined that subsidence is influenced by the implant’s bone interface topology. Indenters with increased line length contact had greater resistance to subsidence in all foam densities.

CONCLUSION

Implant interface topology plays a significant role in preventing subsidence. Similar to the snowshoe principle, increased line length contact at the bone-implant interface leads to an increased resistance to subsidence.

A related study was conducted utilizing a truss implant with a snowshoe interface and an annular implant design. The results of this study confirmed that increased line length contact also provides improved resistance to subsidence of interbody fusion devices (Fig 2).

Achieving implant-specific resistance to subsidence through design modifications that optimize contact topology confirms that Truss Implant TechnologyTM provides design elements that can contribute to improved clinical outcomes.

Full publication available at Journal of Biomechanical Engineering Vol. 142 / 091003-1